Dfmea Template

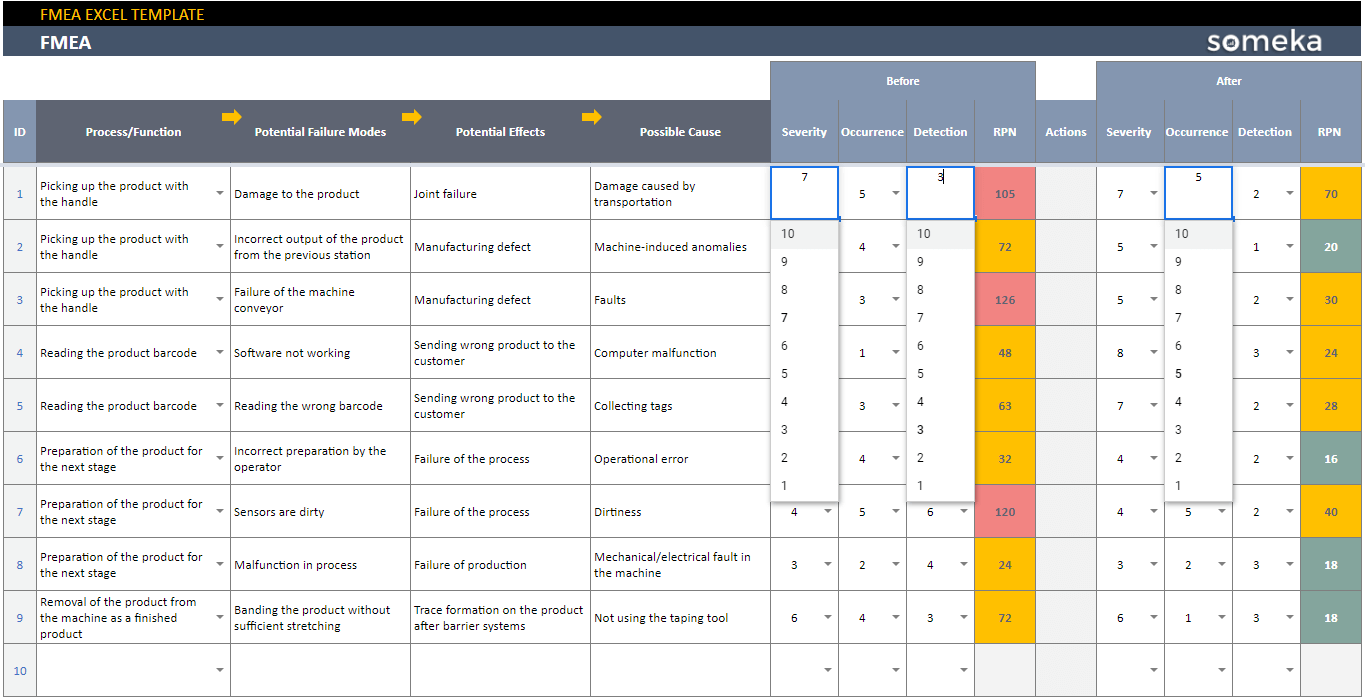

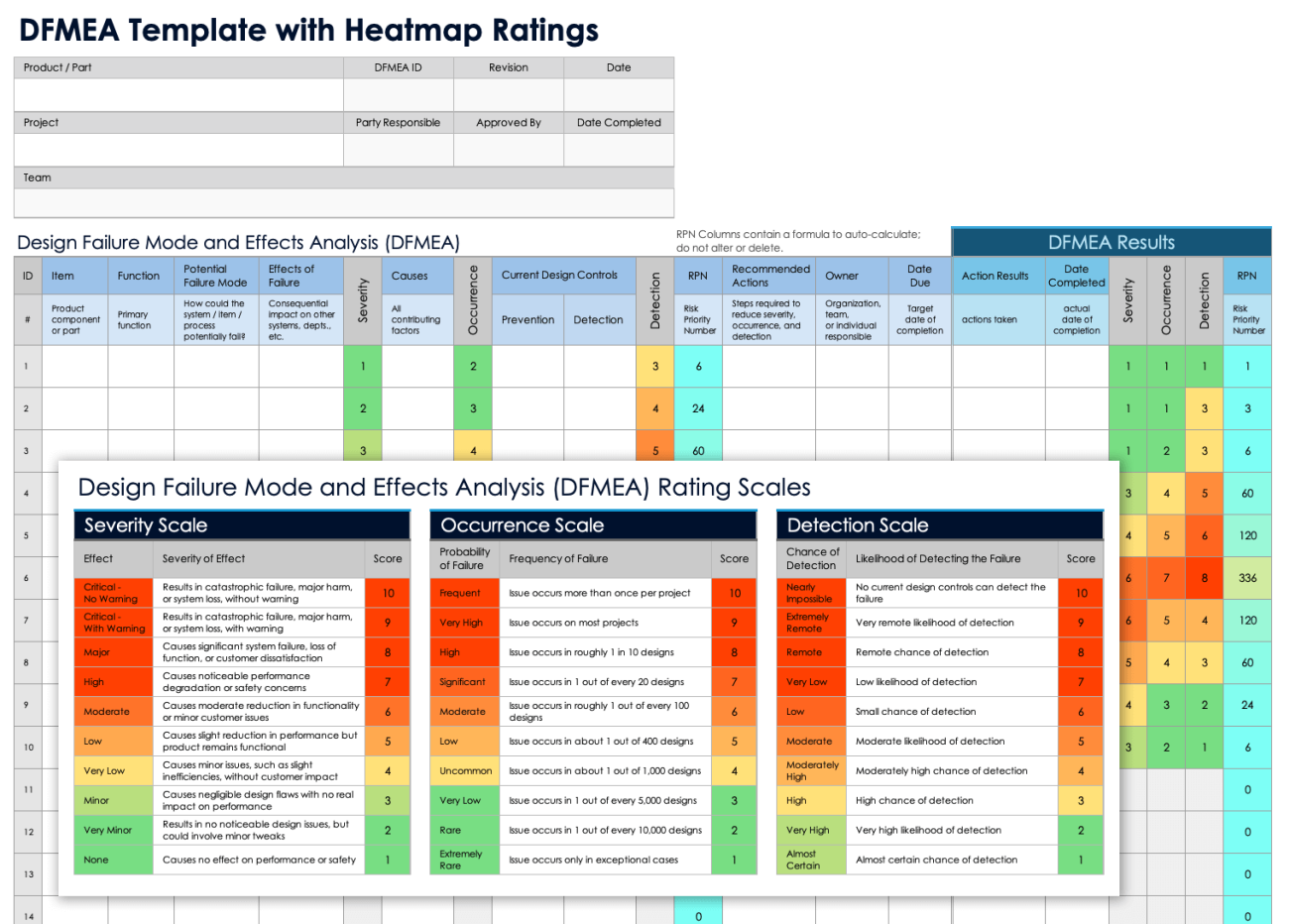

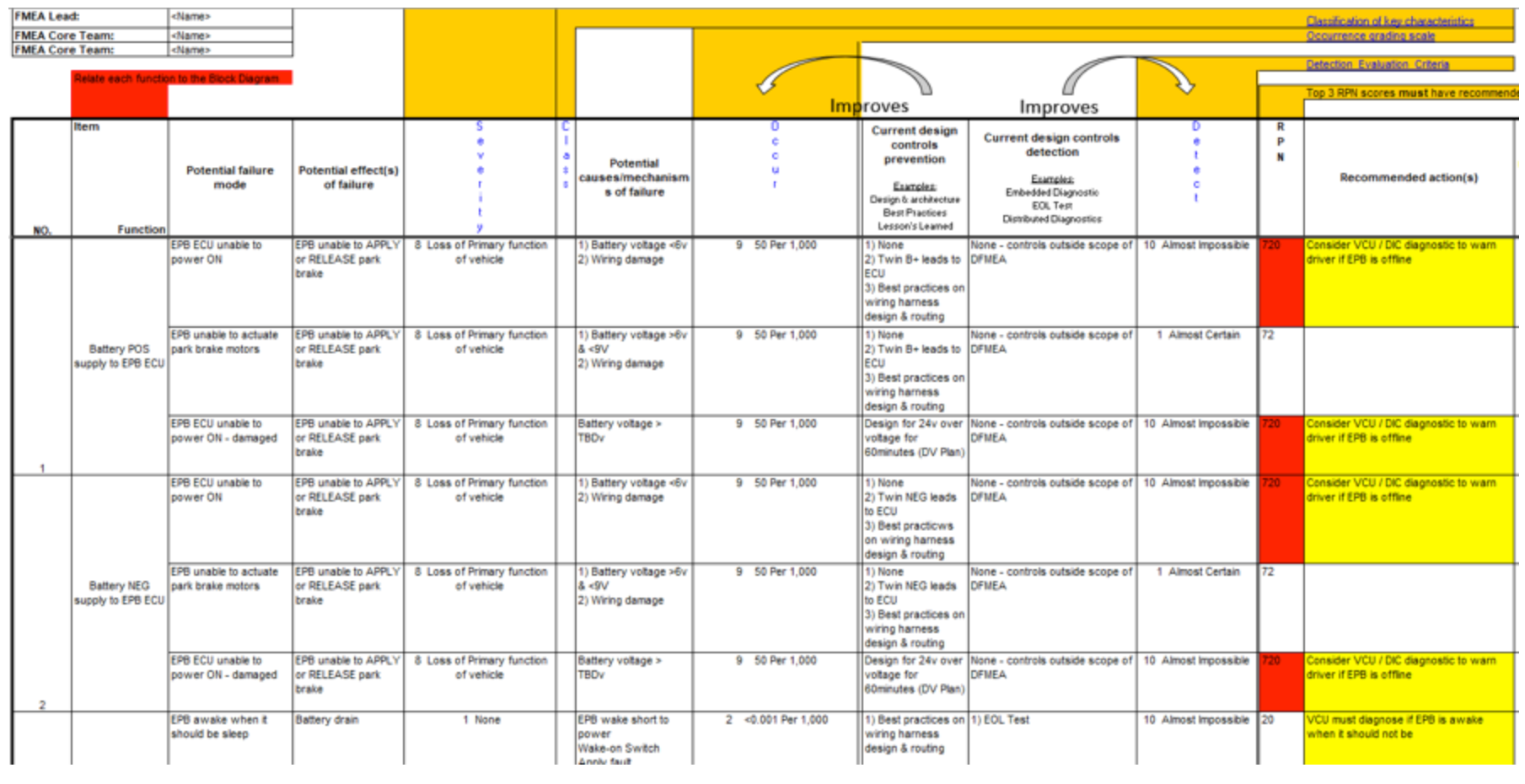

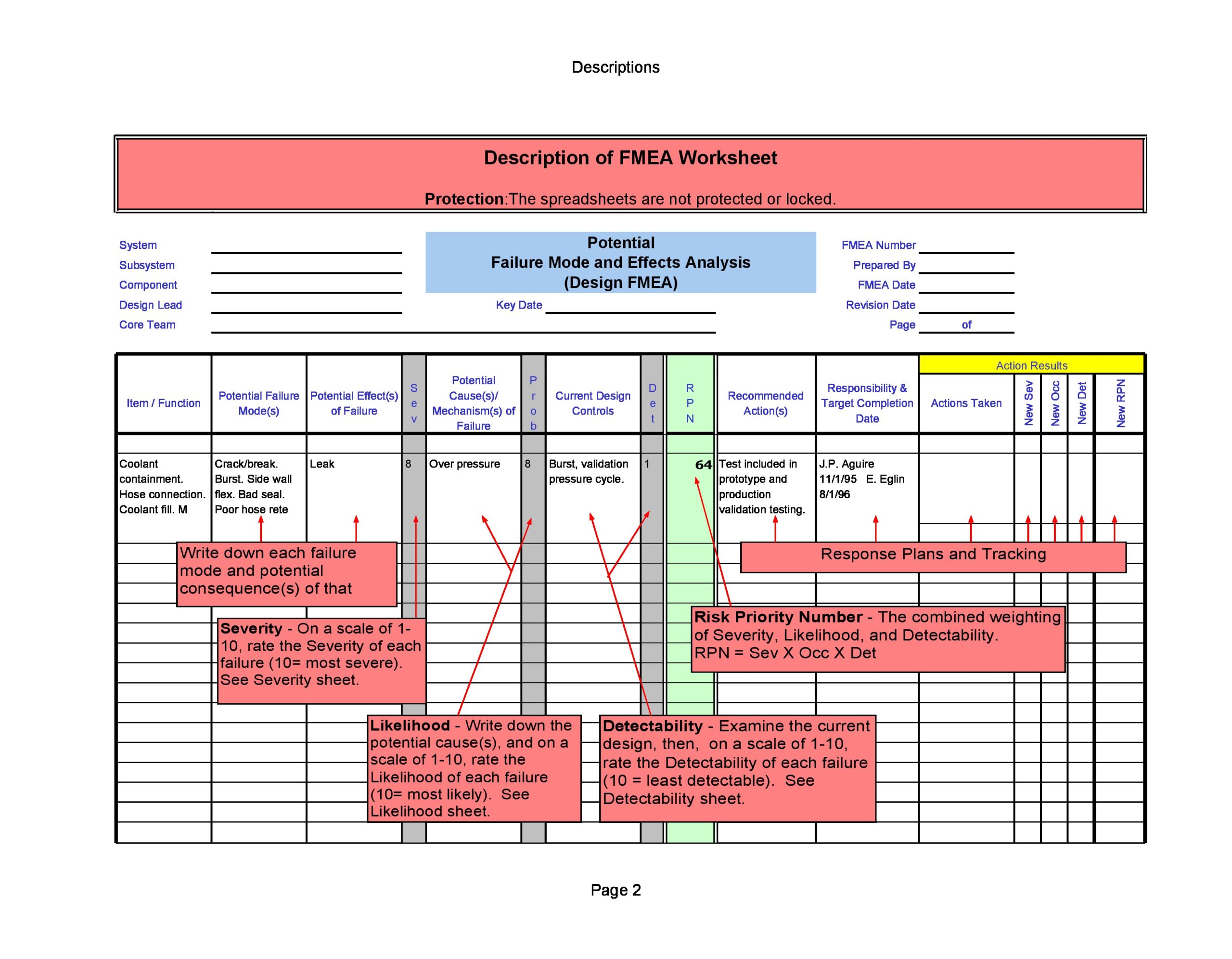

Dfmea Template - The purpose of fmea analysis is to provide a systematic analysis method to identify potential failure modes of systems, components and/or assemblies. Download lumiform’s free design fmea template today and implement a robust strategy for managing design risks. Download fmea form, control plan, process flow diagram, qfd, and more fmea tools for. Then structure analysis will give you a better picture. Dfmea creation starts with the planning step where you can define the scope and collect basic inputs for dfmea creation. Dfmea is a method to improve product quality by analyzi… Design failure mode and effects analysis (dfmea) is a process done by design engineers to ensure that products perform their intended functions and satisfy user needs. This simple template will help you conduct a design fmea as a foundation to learn how to apply the practice in your design workflow. It is created for a new design and updated whenever new faults are discovered, or. This document appears to be a template for a design failure modes and effects analysis (fmea). Design failure mode and effects analysis (dfmea) is a process done by design engineers to ensure that products perform their intended functions and satisfy user needs. Design fmea (dfmea) this type of fmea analysis explores the probability of reduced product life, product malfunctions, and even regulatory and safety concerns taken. The template includes sections for item information like the item being analyzed, model year,. Download fmea form, control plan, process flow diagram, qfd, and more fmea tools for. Dfmea (design failure mode and effects analysis) helps to identify potential risks in a system or component. Then structure analysis will give you a better picture. Design failure mode and effect analysis (dfmea) is a proactive approach to identifying and addressing potential design failures to improve product reliability and safety. It is created for a new design and updated whenever new faults are discovered, or. The purpose of fmea analysis is to provide a systematic analysis method to identify potential failure modes of systems, components and/or assemblies. Dfmea creation starts with the planning step where you can define the scope and collect basic inputs for dfmea creation. Dfmea creation starts with the planning step where you can define the scope and collect basic inputs for dfmea creation. Learn what dfmea is, why and when to use it, and how to conduct it with a template and examples. Pfmea, dfmea, and more excel templates for 7 steps of failure modes and effects analysis. It is created for a. Dfmea (design failure mode and effects analysis) helps to identify potential risks in a system or component. The template includes sections for item information like the item being analyzed, model year,. Design failure mode and effects analysis (dfmea) is a process done by design engineers to ensure that products perform their intended functions and satisfy user needs. This simple template. It is created for a new design and updated whenever new faults are discovered, or. Dfmea is a method to improve product quality by analyzi… Download lumiform’s free design fmea template today and implement a robust strategy for managing design risks. The purpose of fmea analysis is to provide a systematic analysis method to identify potential failure modes of systems,. When everything is ready, the dfmea team, templates and supporting documents, you can start executing the fmea design by following the 9 steps below: Dfmea (design failure mode and effects analysis) helps to identify potential risks in a system or component. It is created for a new design and updated whenever new faults are discovered, or. This document appears to. When everything is ready, the dfmea team, templates and supporting documents, you can start executing the fmea design by following the 9 steps below: Dfmea (design failure mode and effects analysis) helps to identify potential risks in a system or component. Design fmea (dfmea) this type of fmea analysis explores the probability of reduced product life, product malfunctions, and even. Dfmea creation starts with the planning step where you can define the scope and collect basic inputs for dfmea creation. The template includes sections for item information like the item being analyzed, model year,. Design failure mode and effect analysis (dfmea) is a proactive approach to identifying and addressing potential design failures to improve product reliability and safety. This simple. This document appears to be a template for a design failure modes and effects analysis (fmea). This simple template will help you conduct a design fmea as a foundation to learn how to apply the practice in your design workflow. The purpose of fmea analysis is to provide a systematic analysis method to identify potential failure modes of systems, components. Design failure mode and effect analysis (dfmea) is a proactive approach to identifying and addressing potential design failures to improve product reliability and safety. This simple template will help you conduct a design fmea as a foundation to learn how to apply the practice in your design workflow. The purpose of fmea analysis is to provide a systematic analysis method. It is created for a new design and updated whenever new faults are discovered, or. Download fmea form, control plan, process flow diagram, qfd, and more fmea tools for. This simple template will help you conduct a design fmea as a foundation to learn how to apply the practice in your design workflow. Then structure analysis will give you a. Design fmea (dfmea) this type of fmea analysis explores the probability of reduced product life, product malfunctions, and even regulatory and safety concerns taken. Download lumiform’s free design fmea template today and implement a robust strategy for managing design risks. Design failure mode and effects analysis (dfmea) is a process done by design engineers to ensure that products perform their. Design fmea (dfmea) this type of fmea analysis explores the probability of reduced product life, product malfunctions, and even regulatory and safety concerns taken. Then structure analysis will give you a better picture. Design failure mode and effects analysis (dfmea) is a process done by design engineers to ensure that products perform their intended functions and satisfy user needs. This document appears to be a template for a design failure modes and effects analysis (fmea). When everything is ready, the dfmea team, templates and supporting documents, you can start executing the fmea design by following the 9 steps below: The purpose of fmea analysis is to provide a systematic analysis method to identify potential failure modes of systems, components and/or assemblies. Download fmea form, control plan, process flow diagram, qfd, and more fmea tools for. Design failure mode and effect analysis (dfmea) is a proactive approach to identifying and addressing potential design failures to improve product reliability and safety. Dfmea (design failure mode and effects analysis) helps to identify potential risks in a system or component. The template includes sections for item information like the item being analyzed, model year,. This simple template will help you conduct a design fmea as a foundation to learn how to apply the practice in your design workflow. Dfmea creation starts with the planning step where you can define the scope and collect basic inputs for dfmea creation. It is created for a new design and updated whenever new faults are discovered, or.DFMEA Design Failure Mode and Effects Analysis SafetyCulture

Chapter 2 Design Failure Mode & Effects Analysis (DFMEA

Dfmea Sheet

Free FMEA Templates DFMEAs, PFMEAs, System & Service

FMEA Template for Excel, Download & Quick Tips IQASystem

DFMEA Download 1 FMEA Creator for DFMEA FMEA Analysis

Dfmea Template Design

Dfmea Template

Design Fmea Template

Dfmea Template PDF Safety

Download Lumiform’s Free Design Fmea Template Today And Implement A Robust Strategy For Managing Design Risks.

Dfmea Is A Method To Improve Product Quality By Analyzi…

Pfmea, Dfmea, And More Excel Templates For 7 Steps Of Failure Modes And Effects Analysis.

Learn What Dfmea Is, Why And When To Use It, And How To Conduct It With A Template And Examples.

Related Post: