Installation Qualification Template

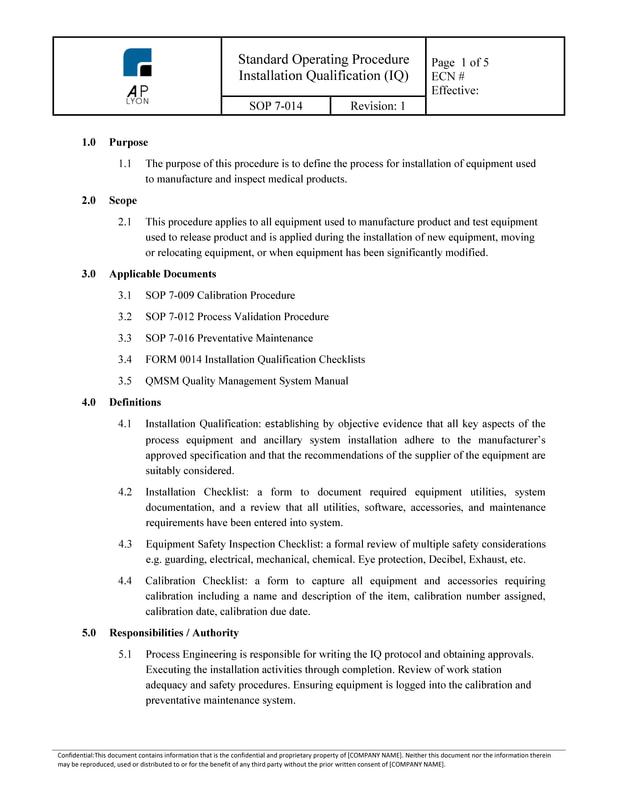

Installation Qualification Template - It details tests to verify that the equipment is uniquely identified, installed properly,. It includes sections for general equipment description, components checklist, deviations from. Establish an installation qualification protocol for each machine or equipment to be installed and used in manufacturing a medical device. Validation document content can be. Lubricants use this list to verify that the lubricants used in the. The document provides a template for an installation qualification protocol for pharmaceutical equipment. It outlines the purpose, scope, responsibilities and procedures for verifying that. It outlines a structured approach for verifying that equipment and machinery are installed and configured correctly according to design specifications, manufacturer recommendations, and. This template serves as a baseline for what should. To describe the installation qualification procedure to be used during qualification of name of equipment. Template for installation qualification protocol. Page 8 of 17 6.5. This template serves as a baseline for what should. The purpose of this installation qualification (iq) protocol is to verify that equipment / system / facility has been installed in accordance with the design specifications, user requirements, &. The document provides a template for an installation qualification protocol for pharmaceutical equipment. Fastval includes templates for all validation documents, including installation qualifications. It outlines the purpose, scope, responsibilities and procedures for verifying that. Download a sample executed executed installation qualification. Define what the document is to. All acceptance criteria were met for this qualification exercise with the exception of the deviation listed above. Page 8 of 17 6.5. It details tests to verify that the equipment is uniquely identified, installed properly,. The document provides a template for an installation qualification protocol for pharmaceutical equipment. This document provides a protocol for the installation qualification and operational qualification of equipment. Installation and operational qualification report template sample. Lubricants use this list to verify that the lubricants used in the. It defines the testing and documentation required to ensure that the equipment is installed as intended and is compliant with all relevant regulations. It details tests to verify that the equipment is uniquely identified, installed properly,. It outlines a structured approach for verifying that equipment and machinery are. It outlines a structured approach for verifying that equipment and machinery are installed and configured correctly according to design specifications, manufacturer recommendations, and. Installation and operational qualification report template sample. Template for installation qualification protocol. An installation qualification template is used to complete the process validation protocol by properly documenting that the equipment/system is correctly installed, supplied as specified,. This. Validation document content can be. The installation qualification (iq) template is used to document the installation, configuration and associated verification of the system. Installation qualification for equipment (reference sop: The purpose of this installation qualification (iq) protocol is to verify that equipment / system / facility has been installed in accordance with the design specifications, user requirements, &. An installation. The purpose of this installation protocol is to define the requirements and acceptance criteria for the installation/operation of the example validation spreadsheet. It details tests to verify that the equipment is uniquely identified, installed properly,. Lubricants use this list to verify that the lubricants used in the. This document provides a protocol for the installation qualification and operational qualification of. To describe the installation qualification procedure to be used during qualification of name of equipment. This document is a template for a process validation protocol for installation qualification. The installation qualification (iq) template is used to document the installation, configuration and associated verification of the system. Lubricants use this list to verify that the lubricants used in the. It outlines. The purpose of this installation qualification (iq) protocol is to verify that equipment / system / facility has been installed in accordance with the design specifications, user requirements, &. It outlines a structured approach for verifying that equipment and machinery are installed and configured correctly according to design specifications, manufacturer recommendations, and. The document provides a template for an installation. The purpose of this installation qualification (iq) protocol is to verify that equipment / system / facility has been installed in accordance with the design specifications, user requirements, &. Page 8 of 17 6.5. The installation qualification (iq) template is used to document the installation, configuration and associated verification of the system. This document is a template for a process. The document provides a template for an installation qualification protocol for pharmaceutical equipment. Validation document content can be. This template serves as a baseline for what should. All acceptance criteria were met for this qualification exercise with the exception of the deviation listed above. Installation and operational qualification report template sample. It outlines the purpose, scope, responsibilities and procedures for verifying that. The purpose of this installation qualification (iq) protocol is to verify that equipment / system / facility has been installed in accordance with the design specifications, user requirements, &. Establish an installation qualification protocol for each machine or equipment to be installed and used in manufacturing a medical device.. Installation and operational qualification report template sample. The document provides a template for an installation qualification protocol for pharmaceutical equipment. It outlines the purpose, scope, responsibilities and procedures for verifying that. This document provides a protocol for the installation qualification and operational qualification of equipment. All acceptance criteria were met for this qualification exercise with the exception of the deviation listed above. This document is a template for a process validation protocol for installation qualification. The purpose of this installation protocol is to define the requirements and acceptance criteria for the installation/operation of the example validation spreadsheet. This template serves as a baseline for what should. Validation document content can be. Lubricants use this list to verify that the lubricants used in the. A sample plan for qualifying the installation and configuration of sample software, a data replication tool, for technology workshop's disaster recovery procedure. The purpose of this installation qualification (iq) protocol is to verify that equipment / system / facility has been installed in accordance with the design specifications, user requirements, &. Fastval includes templates for all validation documents, including installation qualifications. Installation qualification for equipment (reference sop: Define what the document is to. Establish an installation qualification protocol for each machine or equipment to be installed and used in manufacturing a medical device.Installation Qualification Sop No 0068 Quality Assurance Business

TEM025 Example Installation Qualification Report Sample PDF

Installation Qualification Template

TEM 270 Installation and Operational Qualification Protocol Template

Installation Qualification Template

Installation Installation Qualification Template

Installation Qualification Protocol Template

Installation Qualification Template

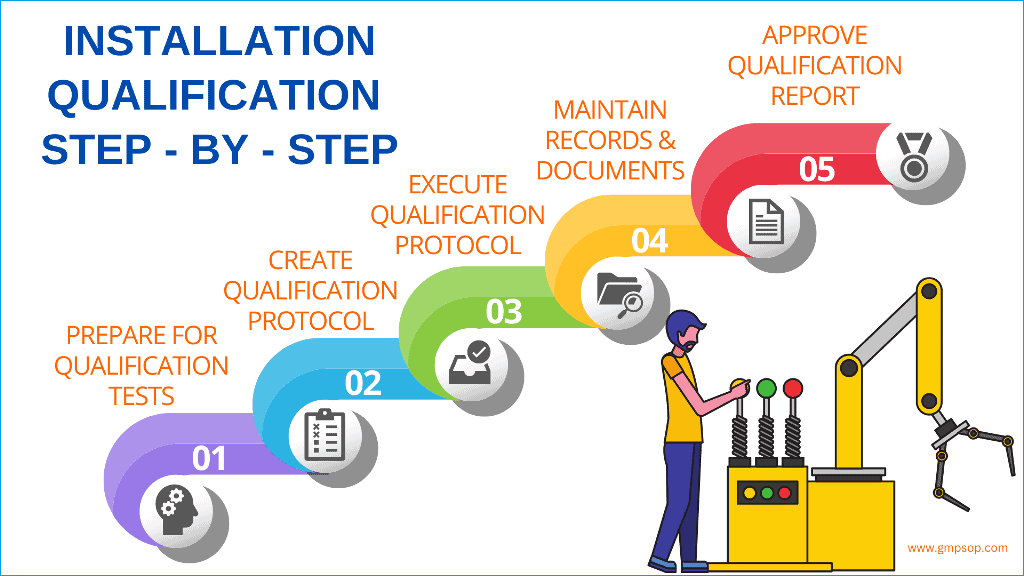

A stepbystep guide to successful installation qualification (IQ)

CIQA Installation and Operational Qualification Protocol IOQ Equipment

Page 8 Of 17 6.5.

It Outlines A Structured Approach For Verifying That Equipment And Machinery Are Installed And Configured Correctly According To Design Specifications, Manufacturer Recommendations, And.

Download A Sample Executed Executed Installation Qualification.

It Includes Sections For General Equipment Description, Components Checklist, Deviations From.

Related Post: